For more than a decade, Industry 4.0 has been the defining term for digital transformation in manufacturing. It brought connected machines, industrial IoT, data analytics, and automation systems that could make real-time decisions. Now, a new era is emerging — Industry 5.0 — and it’s changing how manufacturers, automation engineers, and technology providers think about production, people, and progress.

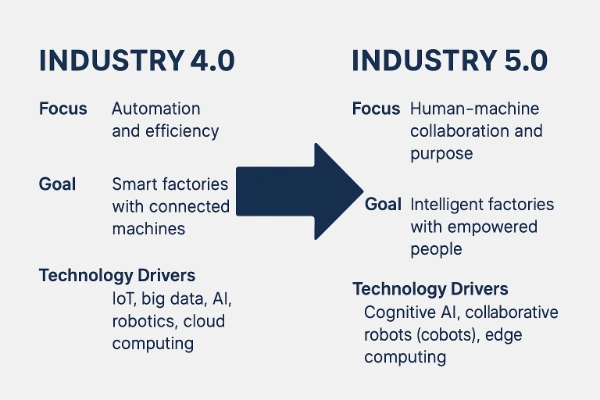

While Industry 4.0 focused on automation and efficiency, Industry 5.0 focuses on collaboration and purpose. It’s not about replacing humans with robots but about humans and machines working together in a smarter, more sustainable, and more resilient industrial ecosystem.

In this article, we’ll explore what Industry 5.0 is, how it differs from Industry 4.0, and what this shift means for automation providers and manufacturers moving forward.

What Is Industry 5.0?

Industry 5.0 represents the next evolution of industrial automation — one that blends human creativity and cognitive ability with the precision and power of advanced technologies such as AI, robotics, and data analytics. The European Commission defines it as “a vision of industry that aims beyond efficiency and productivity as the sole goals and reinforces the role and contribution of industry to society.” (Source: European Commission Industry 5.0 Initiative – https://ec.europa.eu/info/research-and-innovation/research-area/industrial-research-and-innovation/industry-50_en)

At its core, Industry 5.0 emphasizes three main pillars:

1. Human-centric manufacturing – Empowering workers with smart tools and intuitive interfaces rather than replacing them.

2. Sustainability – Designing systems that minimize waste, reduce carbon emissions, and maximize resource efficiency.

3. Resilience – Building flexible production systems that can adapt quickly to disruption, whether caused by supply chain breakdowns, pandemics, or material shortages.

These principles recognize that technology alone doesn’t create progress — people do. In Industry 5.0, technology enhances human potential, not the other way around.

From Industry 4.0 to Industry 5.0: The Key Differences

Industry 4.0 optimized processes; Industry 5.0 humanizes them. Automation providers who thrived in the Industry 4.0 era by delivering PLCs, HMIs, and SCADA integrations will now need to extend their value — designing automation systems that empower operators, support sustainability, and communicate insights across the entire production ecosystem.

The Rise of Human-Machine Collaboration

One of the defining characteristics of Industry 5.0 is the reunion of humans and machines. Rather than full automation that excludes people, this new paradigm embraces a collaborative workspace where cobots (collaborative robots), AI assistants, and augmented reality interfaces help human workers perform better, safer, and more creatively. (Learn more about cobots: https://www.universal-robots.com/what-is-a-cobot/)

Examples include technicians wearing AR glasses to visualize live process data, workers collaborating with cobots, and engineers using AI-powered predictive analytics to make proactive maintenance decisions.

The Role of Artificial Intelligence and Data in Industry 5.0

Data remains the lifeblood of modern manufacturing. However, in Industry 5.0, data isn’t just about dashboards and KPIs — it’s about context and cognition. Advanced AI systems interpret process data in real time, recommend adjustments, and learn from human feedback to continuously improve. (See AI in Manufacturing insights: https://www.mckinsey.com/capabilities/operations/our-insights/the-future-of-ai-in-manufacturing)

Sustainability: A Core Value of Industry 5.0

Sustainability isn’t an afterthought in Industry 5.0 — it’s a design requirement. Manufacturers are under growing pressure to reduce carbon footprints and optimize energy use. Industry 5.0 automation systems enable real-time energy monitoring, predictive maintenance, and smart material tracking to minimize waste. (Explore sustainable manufacturing: https://www.epa.gov/smm/sustainable-management-materials-manufacturing)

Resilience Through Flexible and Adaptive Automation

If recent global disruptions taught us anything, it’s that rigid automation systems can crumble under volatility. Industry 5.0 encourages modular, flexible, and adaptive architectures using edge computing and cloud integration. (Learn more: https://www.rockwellautomation.com/en-us/company/news/the-journal/edge-computing-in-manufacturing.html)

Industry 5.0 in Practice: Real-World Examples

Collaborative Robotics in Automotive Assembly

Leading automakers integrate cobots to work safely with technicians, boosting productivity without losing craftsmanship.

AI-Driven Predictive Maintenance in Food Processing

AI algorithms detect early signs of wear, alerting maintenance teams before failures occur — reducing waste and downtime.

Circular Manufacturing in Electronics

Manufacturers use traceability systems and closed-loop recycling models supporting sustainability goals central to Industry 5.0.

Augmented Reality Training in Industrial Automation

AR-based training modules allow operators to learn on the job, guided by overlays that reduce human error.

What Industry 5.0 Means for Automation Providers

For automation system integrators and technology providers like Twilight Automation, the transition to Industry 5.0 is both a challenge and an opportunity. Clients expect systems that make workers more capable — not obsolete — while emphasizing sustainability, AI, and interoperability.

Preparing for the Future: Steps Manufacturers Can Take Now

1. Assess your current automation maturity and identify where Industry 5.0 technologies can add value.

2. Invest in workforce upskilling for AI, cobots, and data literacy.

3. Adopt modular, scalable automation systems that evolve with market needs.

4. Embed sustainability metrics directly in your control and monitoring systems.

5. Collaborate with trusted automation partners experienced in Industry 5.0 integration.

The Human Touch in a Smart Future

Industry 5.0 isn’t about abandoning automation; it’s about elevating it. It represents a shift from technology-driven manufacturing to purpose-driven manufacturing, where human creativity, sustainability, and resilience guide innovation. The future of manufacturing isn’t only automated — it’s collaborative, sustainable, and human-centered.

Learn more about Industry 5.0 from authoritative sources like the European Commission and Deloitte.