Electrical Automation Trends in 2025

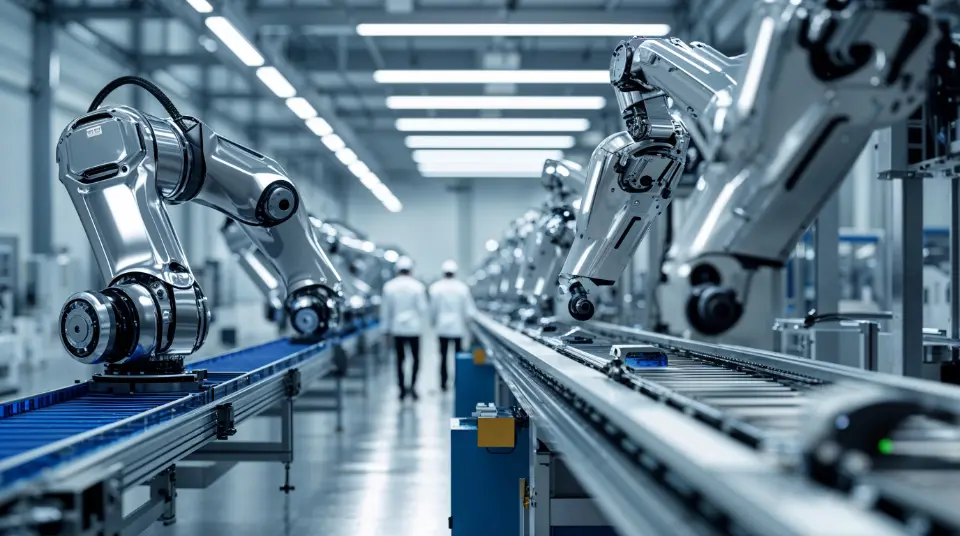

The manufacturing industry is undergoing a significant transformation with the rise of electrical automation. In 2025, this innovative approach is set to redefine traditional production methods and bring about a new era of efficiency and flexibility.

In this article, we will explore the key trends that are driving this change, including:

- The integration of artificial intelligence (AI) and digital tools

- The role of automation engineering in streamlining processes

- The concept of software-defined factories for agile operations

We will also discuss the benefits these technologies bring to manufacturers, such as increased productivity, cost savings, and improved adaptability.

Join us as we dive deeper into the world of electrical automation and discover why it has become an essential strategy for businesses aiming to succeed in the ever-evolving manufacturing landscape of 2025.

Current Landscape of Electrical Automation in Manufacturing

The industrial automation trends in 2025 show a rapid shift towards interconnected and intelligent manufacturing environments. Electrical automation is a crucial part of this development, allowing factories to function with more accuracy, adaptability, and effectiveness.

Key developments include:

- Smart Manufacturing Integration: Combining electrical automation with IoT sensors, data analytics, and machine learning creates adaptive production systems. These smart manufacturing practices improve real-time decision-making and predictive maintenance.

- Flexible Production Lines: Automation systems are designed to quickly reconfigure for different products or volumes. This agility addresses fluctuating market demands without sacrificing quality or speed.

- Collaborative Robotics: Robots work alongside human operators safely and efficiently, optimizing workflows and reducing repetitive strain injuries.

Companies like Rockwell Automation play a crucial role by providing comprehensive hardware and software solutions tailored to modern manufacturing needs. Their platforms integrate control systems with cloud-based analytics, helping manufacturers enhance productivity while maintaining operational resilience.

Manufacturing automation now emphasizes connectivity, data-driven insights, and scalable solutions that support both legacy equipment and new technologies. This combination sets the stage for ongoing innovation throughout the production lifecycle.

Key Technologies Driving Electrical Automation in 2025

The integration of AI and digital tools in manufacturing processes is revolutionizing production and supply chain management. Advances in automation engineering are fostering the development of flexible and resilient production lines, adapting quickly to changing demands. Additionally, the concept of software-defined factories is simplifying operations and offering benefits such as increased efficiency and scalability. These key technologies are reshaping the landscape of electrical automation in 2025, paving the way for more agile and dynamic manufacturing processes.

- Integration of AI and digital tools for enhanced production and supply chain management.

- Advances in automation engineering enabling flexible and resilient production lines.

- Concept and benefits of software-defined factories simplifying operations.

Enhancing Production Efficiency and Agility Through Automation

Electrical automation is a key driver in boosting production efficiency by streamlining processes and minimizing downtime. Automated systems continuously monitor equipment health, predict maintenance needs, and adjust operations in real time to prevent bottlenecks. This proactive approach keeps production lines running smoothly with fewer interruptions.

Flexible production lines powered by electrical automation allow manufacturers to quickly switch between product variants without extensive retooling. This adaptability supports just-in-time manufacturing and responsiveness to market demand shifts.

Examples highlight how agility is achieved through:

- Modular automation components that can be reconfigured rapidly.

- Robotic workcells capable of handling diverse tasks on the same line.

- AI-driven scheduling optimizing resource allocation dynamically.

Such adaptable systems enable manufacturers to meet fluctuating customer needs while maintaining high throughput. The transformation in 2025 shows how electrical automation empowers businesses to respond swiftly without sacrificing quality or efficiency, a critical advantage in today’s competitive landscape.

Sustainability and Energy Management in Automated Manufacturing

Sustainability and energy management are becoming central pillars in manufacturing, driven by increasing regulatory pressure and corporate responsibility goals. Electrical automation plays a crucial role in advancing green manufacturing initiatives by enabling precise control over energy consumption and minimizing waste.

Key trends emphasize:

- Energy-efficient automation solutions that optimize machine operation schedules and reduce power usage during idle times.

- Real-time monitoring systems that track energy metrics across production lines, allowing immediate adjustments to improve efficiency.

- Integration of renewable energy sources through smart grid connectivity, facilitated by automated control systems.

Electrical automation supports sustainable manufacturing goals by:

- Lowering the carbon footprint through optimized resource utilization.

- Enhancing process consistency to reduce defects and material scrap.

- Enabling circular economy practices by automating recycling and reuse workflows within factories.

Companies adopting these technologies experience measurable reductions in energy costs while contributing to environmental stewardship, aligning profitability with sustainability efforts.

Cybersecurity, Safety, and Labor Shortages: Challenges Addressed by Electrical Automation Solutions

In the ever-evolving landscape of manufacturing, challenges such as cybersecurity threats, safety concerns, and labor shortages can hinder progress and efficiency. However, electrical automation solutions have emerged as a powerful tool to address these issues head-on.

Importance of Integrating Cybersecurity within Automation

Protecting data and intellectual property (IP) is paramount in automated manufacturing processes. With the increasing reliance on interconnected systems and the Internet of Things (IoT), the risk of cyber threats looms larger than ever. To safeguard against these vulnerabilities, robust cybersecurity measures need to be integrated into automation systems.

- Implementing encryption protocols to secure data transmission

- Conducting regular vulnerability assessments and penetration testing

- Establishing multi-factor authentication for system access

By proactively addressing cybersecurity risks, manufacturers can ensure the integrity of their operations and protect valuable assets from potential attacks.

Safety Features for Workers and Equipment

The well-being of workers and the protection of equipment are critical aspects of any manufacturing environment. Electrical automation solutions prioritize safety by incorporating advanced safety features that mitigate risks.

- Utilizing machine vision systems to detect anomalies and prevent accidents

- Implementing emergency stop buttons and safety interlocks for immediate shutdown

- Designing ergonomic workstations to reduce physical strain on operators

These safety measures not only comply with industry regulations but also foster a culture of safety within organizations. By investing in automated systems that prioritize safety, manufacturers can create a secure working environment for their employees.

Addressing Labor Shortages

The manufacturing industry faces challenges due to labor shortages. Factors such as an aging workforce, skill gaps, and changing job preferences contribute to this issue. However, electrical automation offers a solution by enabling workforce optimization and upskilling.

- Identifying repetitive tasks that can be automated

- Providing training programs to equip workers with new skills

- Redesigning job roles to focus on higher-value activities

Automated processes can fill the gaps created by labor shortages, leading to increased operational efficiency and productivity. Moreover, by empowering workers through upskilling initiatives, manufacturers can cultivate a resilient workforce capable of adapting to technological advancements.

In conclusion, electrical automation solutions play a crucial role in overcoming challenges faced by the manufacturing industry. By integrating cybersecurity measures, prioritizing safety features, and addressing labor shortages through optimization strategies, manufacturers can pave the way for sustainable growth in an increasingly competitive landscape.

Future Outlook: Predictions for Electrical Automation Beyond 2025

The future of electrical automation in manufacturing beyond 2025 holds exciting possibilities with the emergence of cutting-edge technologies that will reshape the industry landscape. Here are some key points to consider:

1. Emerging Technologies

Innovations such as Internet of Things (IoT), 5G connectivity, and edge computing are poised to revolutionize manufacturing processes, enabling real-time data analytics, predictive maintenance, and enhanced decision-making capabilities.

2. Continuous Digital Transformation

The integration of advanced digital tools like machine learning and Augmented Reality (AR) into automation systems will be pivotal in driving operational efficiencies, reducing costs, and ensuring sustainable growth in the competitive manufacturing sector.

As we look ahead, the seamless fusion of these technologies with electrical automation will pave the way for smarter factories, agile production lines, and dynamic supply chains, setting new benchmarks for efficiency, sustainability, and innovation in the manufacturing domain.

Real-World Case Studies Demonstrating Electrical Automation Impact

Tesla’s Manufacturing Revolution

Tesla achieved 95% automated production at Gigafactory Shanghai, reducing Model Y assembly time to just 10 hours compared to 30 hours for traditional manufacturers. The company’s smart cart system and 200+ robots per facility have enabled production efficiency gains of up to 50%, with some facilities reaching 3,000 units per week.

Smart Building Energy Savings

Microsoft realized $240,000 in energy savings within 30 days of implementing building automation. Studies show that automating HVAC, lighting, and window shading can reduce energy consumption by 30-50%. Real implementations in Europe demonstrated energy reductions of up to 86% during peak hours and 22% reduction in monthly electricity bills.

Manufacturing ROI Success

A Boston Consulting Group study found companies implementing advanced automation experienced 16% productivity increases and 12% operational cost reductions. The food and beverage industry is seeing 8.5% annual growth in automation adoption, while retrofitted systems show cost savings of around 50% compared to conventional approaches.

Grid Modernization Impact

Shell reduced maintenance costs by 20%, saving an estimated $2 billion annually through AI-powered predictive maintenance systems. China is investing $23 billion in smart grid technology by 2025, while Europe plans €170 billion in grid digitalization by 2030.

Market Growth

The electrical automation market is projected to grow from $261.68 billion in 2025 to $488.92 billion by 2034, with 86% of manufacturing executives viewing smart factory solutions as the primary driver of future competitiveness.

How Modern Automation Manufacturing Processes Can Transform Your Business for 2025

Embracing manufacturing modernization through advanced electrical automation offers clear competitive advantages. You gain:

- Increased production speed and flexibility

- Enhanced product quality and consistency

- Improved energy efficiency and sustainability

- Greater resilience against labor shortages and supply disruptions

How Electrical Automation is Transforming Manufacturing in 2025 is evident in the way businesses optimize operations, reduce costs, and scale innovation rapidly. The future favors those who invest in smart automation solutions today. Adopting these technologies positions your business to lead with agility and sustainability in an ever-evolving industrial landscape.