Manufacturing plants across the Quad Cities and beyond are facing an increasingly urgent decision: when to upgrade aging control systems that have served them faithfully for years or even decades. While the “if it ain’t broke, don’t fix it” mentality has merit, today’s competitive manufacturing environment demands more than just functional equipment—it requires smart, efficient, and future-ready systems.

The statistics paint a sobering picture. The average manufacturer faces 800 hours of unplanned machine maintenance and downtime a year—that’s roughly 15 hours per week of non-productive time. With manufacturing downtime costing approximately $260,000 per hour, the financial impact of outdated control systems extends far beyond the initial investment in upgrades.

Perhaps most concerning is that more than 70 percent of respondents aren’t fully aware of when their equipment is due for maintenance, upgrade or replacement. This lack of visibility creates a ticking time bomb that could explode into costly emergency situations at the worst possible moment.

As electrical engineering and automation specialists at Twilight Automation, we’ve helped numerous manufacturing facilities recognize the warning signs before they become production disasters. Here are five critical indicators that your plant’s control systems need immediate attention.

Sign #1: Frequent Unplanned Downtime and Emergency Repairs

The most obvious red flag is an increase in unexpected production stoppages. While occasional equipment hiccups are normal in any manufacturing environment, frequent emergency shutdowns signal that your control systems are operating on borrowed time.

What to Watch For:

- Production lines stopping without warning

- Increasing frequency of “minor” electrical issues

- Emergency repair calls becoming routine rather than exceptional

- Difficulty diagnosing problems quickly due to outdated diagnostic capabilities

Modern control systems provide real-time monitoring and predictive analytics that can identify potential failures before they occur. Legacy systems, by contrast, often provide little warning before catastrophic failure. Reactive approaches to maintenance average 8.43% unplanned downtime annually, compared to just 5.42% for data/monitoring approaches.

Consider a recent project where we upgraded a local food processing plant’s 20-year-old Allen-Bradley PLC-5 system to ControlLogix. The old system had been causing random production stoppages that cost the company over $50,000 per incident in lost production and overtime labor. After the upgrade, unplanned downtime dropped by 85%, and the predictive maintenance capabilities now alert operators to potential issues days or weeks in advance.

The Hidden Costs: Emergency repairs don’t just cost money—they cost opportunities. Rush shipping for obsolete parts, overtime labor for weekend repairs, and the ripple effects throughout your supply chain all compound the true cost of reactive maintenance strategies.

Sign #2: Obsolete Hardware with Expensive, Hard-to-Find Parts

Nothing strikes fear into a maintenance manager’s heart quite like searching for replacement parts for a control system that was discontinued years ago. When your critical automation components become “legacy” products, you’re operating in dangerous territory.

Warning Signs Include:

- Replacement parts requiring special orders from specialty suppliers

- Lead times measured in weeks or months rather than days

- Costs for spare parts increasing dramatically year over year

- Parts availability becoming increasingly uncertain

Many automation systems were installed decades ago and are approaching obsolescence and technology maturity. The industrial automation industry operates on rapid development cycles, with new technologies emerging every few years. Component manufacturers typically support products for 7-12 years, but PC-based components like HMIs may have lifecycles as short as 3-5 years.

The financial impact extends beyond just the parts themselves. When a critical component fails and requires a hard-to-find replacement, you’re looking at:

- Extended downtime while sourcing parts

- Premium pricing for obsolete components

- Potential production schedule disruptions

- Increased inventory carrying costs for stockpiled spare parts

Strategic Inventory Management: Some manufacturers attempt to mitigate this risk by stockpiling spare parts, but this strategy has limitations. Components can degrade over time, even in storage, and technology advances may make your stockpiled parts incompatible with newer system requirements.

Sign #3: Limited or No Real-Time Data Visibility

In today’s data-driven manufacturing environment, flying blind is not an option. If your control systems can’t provide comprehensive, real-time insights into your operations, you’re missing critical opportunities for optimization and problem prevention.

Indicators of Poor Data Visibility:

- Relying on operator observations rather than system data for decision-making

- Inability to track key performance indicators (KPIs) automatically

- Manual data collection for production reports

- Limited historical data for trend analysis

- Difficulty integrating with modern ERP or MES systems

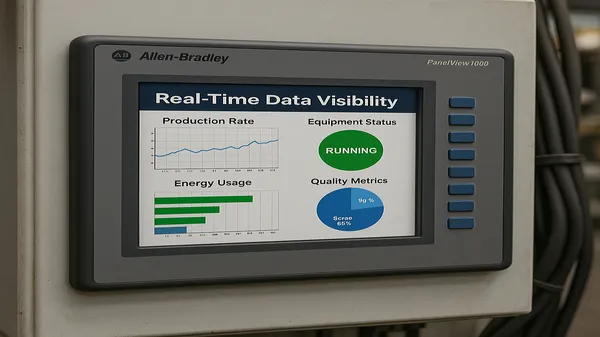

Modern HMI systems and SCADA platforms provide unprecedented visibility into every aspect of your operations. Real-time dashboards can display production rates, energy consumption, quality metrics, and equipment health status all in one integrated view. This visibility enables proactive decision-making rather than reactive problem-solving.

A manufacturing client in the Quad Cities recently discovered that their legacy system was masking significant inefficiencies. After upgrading to a modern Rockwell Automation platform with FactoryTalk View, they identified that one production line was operating 23% below optimal efficiency due to timing issues that weren’t visible in their old system. The data-driven insights from the new system helped them recover that lost production capacity within six weeks.

The Competitive Advantage: Companies that leverage real-time data effectively can respond to market demands faster, optimize their operations more precisely, and maintain higher overall equipment effectiveness (OEE). Without this visibility, you’re essentially competing with one hand tied behind your back.

Sign #4: Cybersecurity Vulnerabilities and Compliance Concerns

Perhaps no aspect of industrial automation has evolved more dramatically than cybersecurity requirements. Legacy control systems were designed in an era when industrial networks were isolated and air-gapped from external threats. Today’s interconnected manufacturing environment demands robust cybersecurity measures that many older systems simply cannot provide.

Cybersecurity Red Flags:

- Systems running outdated operating systems without security updates

- Lack of user authentication and access controls

- Unencrypted communications between devices

- Inability to monitor or log system access

- Non-compliance with industry cybersecurity standards

The consequences of cybersecurity breaches in manufacturing can be devastating. Beyond the immediate operational disruption, companies face potential regulatory fines, litigation risks, and long-term damage to their reputation. Modern control systems incorporate multiple layers of security, including encrypted communications, role-based access controls, and comprehensive audit trails.

Compliance Requirements: Many industries now have specific cybersecurity requirements for manufacturing operations. Whether it’s NIST guidelines, ISO 27001 standards, or industry-specific regulations, compliance often requires capabilities that legacy systems cannot provide. Upgrading your control systems isn’t just about operational efficiency—it’s about regulatory compliance and risk management.

Insurance Implications: Many industrial insurance policies now include cybersecurity requirements and exclusions. Operating with outdated, vulnerable control systems could potentially impact your coverage or claims eligibility.

Sign #5: Inefficient Energy Usage and Environmental Impact

Energy efficiency has become both an economic and environmental imperative for modern manufacturing operations. Legacy control systems often lack the sophisticated algorithms and optimization capabilities needed to minimize energy consumption while maintaining production targets.

Energy Inefficiency Indicators:

- Rising energy costs despite stable production volumes

- Inability to optimize equipment operation during peak rate periods

- Lack of energy monitoring and reporting capabilities

- Equipment running at fixed speeds regardless of demand

- Poor power factor and energy quality issues

Modern control systems incorporate advanced energy management features like variable frequency drives (VFDs), demand response capabilities, and power quality monitoring. These systems can automatically adjust equipment operation based on production requirements, energy pricing, and environmental conditions.

Environmental and Economic Impact: A recent study of manufacturing facilities that upgraded to modern control systems showed average energy savings of 15-30%. For a medium-sized manufacturing plant, this can translate to annual savings of $100,000 or more. Additionally, improved energy efficiency supports sustainability goals and can qualify companies for various energy incentive programs.

Smart Grid Integration: Modern control systems can integrate with smart grid technologies, enabling participation in demand response programs and real-time energy optimization based on grid conditions and pricing.

The Hidden Costs of Delaying Upgrades

While the upfront cost of control system upgrades can seem substantial, the hidden costs of delaying necessary improvements often far exceed the investment required for modernization. Manufacturers that are reactive when it comes to factory automation upgrades will incur more costs than if the upgrades are part of a more proactive plan. These costs compound over time and become increasingly difficult to quantify:

Opportunity Costs: Every day your facility operates with suboptimal control systems, you’re missing opportunities for improved efficiency, quality, and productivity. Competitors with modern systems gain cumulative advantages that become harder to overcome as time passes.

Escalating Maintenance Costs: As systems age, maintenance costs typically increase exponentially rather than linearly. The combination of obsolete parts, specialized expertise requirements, and extended downtime creates a perfect storm of escalating expenses.

Talent Retention Challenges: Skilled technicians and engineers increasingly prefer working with modern technologies. Facilities that rely heavily on legacy systems may find it difficult to attract and retain top talent, further compounding operational challenges.

Making the Business Case for Control System Modernization

When presenting proposals for control system upgrades to leadership, focus on measurable business outcomes rather than technical specifications. Here’s a framework for building a compelling business case:

Calculate Current Costs: Document the true cost of your existing control systems, including:

- Maintenance and repair expenses

- Spare parts inventory carrying costs

- Downtime-related losses

- Energy inefficiencies

- Lost productivity due to system limitations

Quantify Expected Benefits: Modern control systems typically deliver:

- 20-40% reduction in unplanned downtime

- 15-30% improvement in energy efficiency

- 10-25% increase in overall equipment effectiveness

- Significant reduction in maintenance costs

- Enhanced product quality and consistency

Risk Mitigation Value: Consider the value of avoiding catastrophic failures, regulatory compliance issues, and cybersecurity incidents. While these events may seem unlikely, their potential impact can be enormous.

Control System Upgrades: Plan Your Strategy

Successful control system upgrades require careful planning and strategic thinking. Rather than waiting for emergency situations, develop a proactive upgrade roadmap that aligns with your business objectives and operational requirements.

Assessment Phase: Begin with a comprehensive assessment of your current systems, identifying critical vulnerabilities, obsolescence risks, and improvement opportunities. This assessment should include both technical and business considerations.

Phased Implementation: Large-scale control system upgrades don’t have to happen overnight. Develop a phased approach that prioritizes the most critical systems while minimizing operational disruption. This strategy also spreads the financial investment over time and allows for learning from early phases.

Integration Considerations: Ensure that new control systems can integrate effectively with existing equipment and business systems. Modern platforms offer extensive connectivity options, but proper planning is essential for seamless integration.

Training and Support: Factor in the training requirements for your operations and maintenance teams. Modern control systems offer improved functionality, but realizing their full potential requires proper training and ongoing support.

Investing in Your Manufacturing Future

The question isn’t whether your manufacturing plant will need control system upgrades—it’s when and how you’ll address this inevitable requirement. The five signs outlined above serve as early warning indicators that should prompt immediate action rather than continued procrastination.

Aberdeen Research shows that unplanned downtime in manufacturing can cost up to $260,000 per hour, and downtime costs have increased 50% since 2019/20. In this environment, proactive control system upgrades represent not just operational improvements but competitive advantages that can determine long-term business success.

At Twilight Automation, we’ve guided numerous Quad Cities manufacturers through successful control system upgrades, helping them transform operational challenges into competitive advantages. Our comprehensive approach includes assessment, design, implementation, and ongoing support to ensure that your investment delivers maximum value.

The manufacturing landscape continues to evolve rapidly, with Industry 4.0 technologies, sustainability requirements, and competitive pressures driving the need for smarter, more efficient operations. Companies that proactively address control system obsolescence and leverage modern automation technologies will be best positioned to thrive in this dynamic environment.

Don’t wait for emergency situations to force your hand. If your facility is experiencing any of the warning signs discussed above, contact Twilight Automation today for a comprehensive control system assessment. Together, we can develop a strategic upgrade plan that enhances your operational efficiency, reduces your risk exposure, and positions your facility for long-term success.

The future of manufacturing belongs to those who embrace modern control technologies today. Make sure your facility is ready for what’s ahead.

Ready to assess your control system upgrade needs? Contact Twilight Automation at [your contact information] for a comprehensive evaluation of your current systems and a customized upgrade strategy that aligns with your operational goals and budget requirements.